Comparison of several commonly used crushing equipment and characteristics of sand aggregate line:

The production of sand and aggregate is mainly divided into mining, crushing, screening and shaping sand making several links, generally according to the characteristics of raw materials, system scale, site layout conditions, system technology and other equipment selection, the main equipment involved are crusher, vibrating screen, sand making machine, auxiliary equipment with belt conveyor, feeder, stone powder recovery equipment, water supply equipment and dust collector.

Generally speaking, for large sand aggregate production lines, the main equipment, such as coarse crusher, medium and fine crusher, pre-screening and screening equipment, etc. should be more than 2 sets as far as possible, which is conducive to improving the reliability of the system and convenient maintenance.

Crushing equipment is mainly divided into two categories according to the working principle:

One is extrusion crushing equipment: such as jaw crusher, rotary crusher, cone crusher, etc., suitable for crushing raw materials with relatively high abrasion index, low stone powder content in products, but generally broken out of the material needle flake particles, poor pumping performance;

One is impact crushing equipment: such as impact crusher and vertical shaft impact crusher, which is characterized by large material crushing ratio, simple structure, convenient equipment maintenance, good product particle shape, and small material compressive strength loss.

In large aggregate production lines, jaw crusher or rotary crusher is usually used for rough breaking, and cone crusher, impact crusher or hammer crusher is used for medium crushing.

Sand aggregate production line commonly used crusher and its advantages and disadvantages and scope of application are as follows:

1, jaw crusher

Advantages: simple structure, reliable operation, small size, light weight, low configuration height, large feed port, adjustable discharge port, low price;

Disadvantages: the liner wear fast, the product particle shape is not good, the needle sheet is more, the output is low, and the material needs to be forced to feed;

Scope of application: Rock hardness adaptability is good, generally used for raw material crushing, for medium crushing equipment needs to be miniaturized.

2, rotary crusher

Advantages: large single-unit processing capacity, low unit energy consumption, good product particle shape, continuous feeding, no need to feed machine;

Disadvantages: complex structure, high body size, difficult maintenance, high price, small feed size, large amount of civil construction;

Scope of application: Suitable for a variety of hardness rocks, generally used as coarse crushing equipment, minicomputer can also be used in the crushing link.

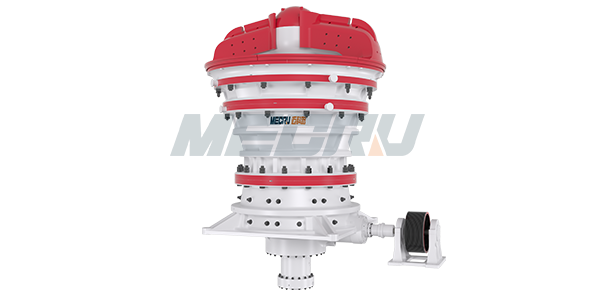

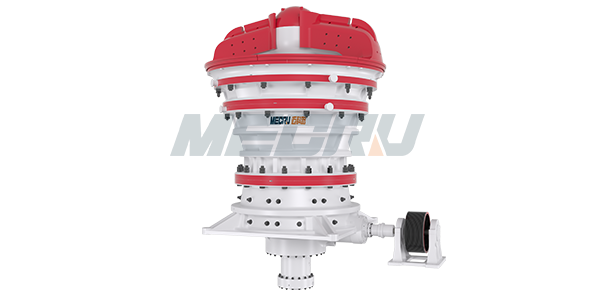

3, cone crusher

Advantages: reliable operation, high yield, uniform particle size, small liner wear;

Disadvantages: complex structure, high maintenance requirements, high body installation size, expensive;

Scope of application: Rock hardness adaptability, aggregate production line is the most commonly used crushing or fine crushing equipment.

4, impact crusher

Advantages: large crushing ratio, fine product, good grain shape, low energy consumption, simple structure;

Disadvantages: the board hammer and liner are easy to wear, and the replacement and maintenance workload is large; Serious dust, not suitable for crushing plastic and viscous materials;

Scope of application: Suitable for crushing medium hard rock, for crushing and sand making equipment, some large equipment is also used for coarse crushing.

5, impact sand making machine

Advantages: It has three functions of crushing, sand making and shaping, and the fineness modulus is adjustable and controllable, making the product excellent particle shape, reasonable grading, cube, and very low needle flake content; High packing density and uniform gradation.

Disadvantages: complex maintenance and high cost, small feed size, suitable for fine crushing and sand making.

Scope of application: It is suitable for sand making and shaping of limestone, river pebbles, granite, ore tailings, etc. It is widely used in construction materials, water conservancy and hydropower, metallurgy, mining, chemical industry and other fields.

The selection of sand and aggregate equipment is the key link of aggregate system design, which directly affects the quality and cost of sand and aggregate production. In the equipment configuration, the nature of the source rock, the grading and quality requirements of the finished aggregate, and the technical performance of the main equipment should be fully studied, which should not only be technologically advanced and economically rational, but also ensure the reliability of the system operation.

+86 139 3711 5575

+86 139 3711 5575 mecru@mecrugroup.com

mecru@mecrugroup.com 8613937115575(Whatsapp/Wechat)

8613937115575(Whatsapp/Wechat) No. 67, Taojia Road, Guangwu Town, Xingyang City, Zhengzhou city, Henan Province, China

No. 67, Taojia Road, Guangwu Town, Xingyang City, Zhengzhou city, Henan Province, China